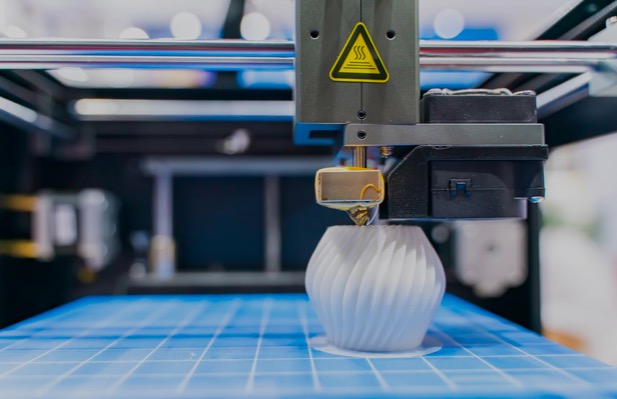

Hearing aids, mouth guards, dental implants, and other highly tailored structures are often products of 3D printing. These structures are typically made via vat photopolymerization — a form of 3D printing that uses patterns of light to shape and solidify a resin, one layer at a time.

The process also involves printing structural supports from the same material to hold the product in place as it’s printed. Once a product is fully formed, the supports are removed manually and typically thrown out as unusable waste.

MIT engineers have found a way to bypass this last finishing step, in a way that could significantly speed up the 3D-printing process. They developed a resin that turns into two different kinds of solids, depending on the type of light that shines on it: Ultraviolet light cures the resin into an highly resilient solid, while visible light turns the same resin into a solid that is easily dissolvable in certain solvents.

The team exposed the new resin simultaneously to patterns of UV light to form a sturdy structure, as well as patterns of visible light to form the structure’s supports. Instead of having to carefully break away the supports, they simply dipped the printed material into solution that dissolved the supports away, revealing the sturdy, UV-printed part.

The supports can dissolve in a variety of food-safe solutions, including baby oil. Interestingly, the supports could even dissolve in the main liquid ingredient of the original resin, like a cube of ice in water. This means that the material used to print structural supports could be continuously recycled: Once a printed structure’s supporting material dissolves, that mixture can be blended directly back into fresh resin and used to print the next set of parts — along with their dissolvable supports.

The researchers applied the new method to print complex structures, including functional gear trains and intricate lattices.

Post time: Aug-21-2025