Soft kin-feel UV coating is a special type of UV resin, which is mainly designed to simulate the touch and visual effects of human skin. It’s fingerprint resistance and remain clean for a long time, strong and durable. Furthermore, there’s no discoloration, no color difference, and resistant to sunlight. Skin-feel UV curing technology is a surface treatment process based on ultraviolet radiation curing. Through the synergistic effect of special light sources (such as excimer UV lamps or UVLED) and formulated resins, the coating can be quickly cured and the surface can be given a delicate and smooth skin-feel effect.

Here are some of the main features and applications of skin-feel UV resin:

Touch: Skin-feel UV resin can provide a delicate, smooth and elastic feeling similar to human skin.

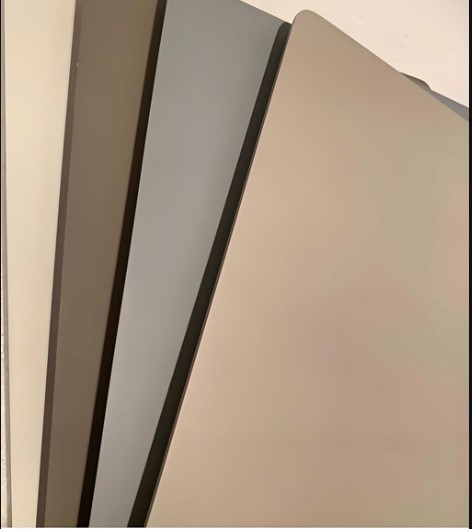

Visual effect: Usually presents a matte color, low gloss, avoid strong reflections and visual fatigue.

Functionality: Scratch-resistant, repairable, and extends the coating service life.

Curing characteristics: UV resin is cured by ultraviolet rays for rapid curing.

Skin-feel UV resin provides a unique surface treatment solution for various products through its unique chemical composition and physical properties, especially in situations where special touch and appearance effects are required.

Core process steps

1- Pretreatment

Ensure the substrate surface is clean, flat, free of oil and impurities, and the moisture content is ≤8%. Different materials such as metal, plastic or wood need to be treated specifically (such as polishing and static removal) to improve adhesion. If the substrate has poor contact (such as glass and metal), promoter needs to be sprayed in advance to enhance adhesion.

2- Skin-feel coating application

Coating selection : UV-curing resins containing fluorinated silicone resins (such as U-Cure 9313) or high-crosslink density polyurethane acrylates (such as U-Cure 9314) to ensure smooth touch, wear resistance and stain resistance.

Coating method : Spraying is the main method, uniform coverage is required to avoid missing coating or accumulation. Each layer needs to be pre-cured when multi-layer coating is applied.

3- Anaerobic environment control (key)

Excimer curing needs to be carried out in an anaerobic environment, and oxygen interference is eliminated by sealing the cavity + deoxidizer to achieve ultra-matte and gloss stability.

4- UV curing process

Light source selection

Excimer light source: 172nm or 254nm wavelength to achieve deep curing and extreme skin-feeling effect

UV LED light source: energy-saving and low temperature (to avoid thermal deformation of the substrate), uniform and controllable light intensity.

Post time: Jun-26-2025