In general, UV printing involves the following categories of technologies:

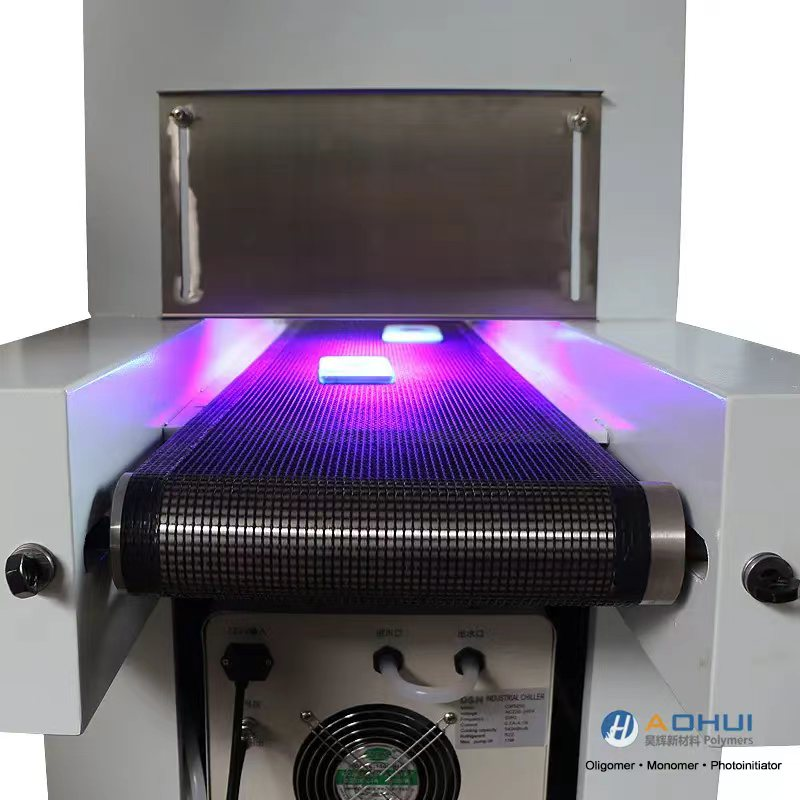

1. UV Light Source Equipment

This includes lamps, reflectors, energy-control systems, and temperature-control (cooling) systems.

(1) Lamps

The most commonly used UV lamps are mercury vapor lamps, which contain mercury inside the tube. In some cases, other metals such as gallium are added to adjust the spectral output.

Metal-halide lamps and quartz lamps are also widely used, and many are still imported.

The wavelength range emitted by UV curing lamps must fall between approximately 200–400 nm to be effective for curing.

(2) Reflectors

The main function of the reflector is to redirect UV radiation back toward the substrate to increase curing efficiency (UV Tech Publications, 1991). Another important role is to help maintain an appropriate lamp operating temperature.

Reflectors are typically made of aluminum, and the reflectance is generally required to reach around 90%.

There are two basic reflector designs: focused (elliptical) and non-focused (parabolic), with additional variations developed by manufacturers.

(3) Energy-Control Systems

These systems ensure that the UV output remains stable, maintaining curing efficiency and consistency while adapting to different printing speeds. Some systems are electronically controlled, while others use microcomputer control.

2. Cooling Systems

Because UV lamps emit not only UV radiation but also infrared (IR) heat, the equipment operates at high temperatures (for example, the surface temperature of quartz-based lamps can reach several hundred degrees Celsius).

Excessive heat can shorten equipment lifespan and may cause substrate expansion or deformation, leading to registration errors during printing. Therefore, cooling systems are critically important.

3. Ink Supply System

Compared with conventional offset inks, UV inks have higher viscosity and greater friction, and they may cause wear on machine components such as blankets and rollers.

Therefore, during printing, ink in the fountain should be continuously agitated, and the rollers and blankets in the ink system should be materials designed specifically for UV printing.

To maintain ink stability and prevent temperature-related viscosity changes, roller temperature-control systems are also important.

4. Heat Dissipation and Exhaust Systems

These systems remove excess heat and ozone generated during ink polymerization and curing.

They typically consist of an exhaust motor and ducting system.

[Ozone generation is mainly associated with UV wavelengths below ~240 nm; many modern systems reduce ozone through filtered or LED sources.]

5. Printing Inks

Ink quality is the most critical factor affecting UV printing results. In addition to influencing color reproduction and gamut, the printability of the ink directly determines adhesion, strength, and abrasion resistance of the final print.

The properties of photoinitiators and monomers are fundamental to performance.

To ensure good adhesion, when wet UV ink contacts the substrate, the surface tension of the substrate (dynes/cm) must be higher than that of the ink (Schilstra, 1997). Therefore, controlling the surface tension of both the ink and substrate is a key technology in UV printing.

6. UV Energy-Measurement Devices

Because factors such as lamp aging, power fluctuations, and printing-speed changes can affect curing, it is essential to monitor and maintain stable UV energy output. Thus, UV-energy measurement technology plays a vital role in UV printing.

Post time: Dec-30-2025